Under the Control of Vibration at Work Regulations all employers must be reducing the risk of HAVS for their employees.

This means the risk from vibration needs to be assessed and control measures put in place to ensure over-exposure doesn’t occur. For more information on vibration risk assessment, download our free Guide: HAVS Risk Assessments and the consequences of getting it wrong.

Reducing the risk of HAVS

In this post, we offer practical advice and guidance on the best ways to reduce the risk of vibration in the workplace.

Elimination

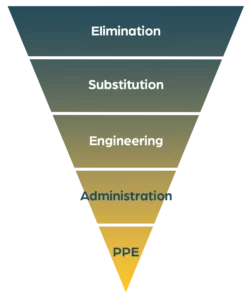

The first step in any vibration risk management strategy is to refer to the Hierarchy of Controls. This model states you should always look to eliminate the source of vibration in the first instance.

The first step in any vibration risk management strategy is to refer to the Hierarchy of Controls. This model states you should always look to eliminate the source of vibration in the first instance.

This can be a change in tool or process used or by changing the approach to the task entirely.

However, in many cases, this is simply not possible and so the risk of HAVS (and whole body vibration) remains. The next steps are to manage the risk of vibration exposure to as low as reasonably practicable (ALARP).

Alternatives

There is a growing market of lower-vibrating tools, normally electric powered in some way, which offer low vibration emissions.

However, these can sometimes be expensive to implement, especially for large asset infrastructures. And it is worth looking into exactly how the tool works. If the tool is emitting lower vibrations due to a reduced speed, for example, it may require longer usage to complete the same task. This would result in greater exposure in the long term as the magnitude might be reduced but the time on tool would be increased.

Make sure you accurately assess the risk from lower-vibration tools before you purchase them.

Tool best practise

There is a lot to be said for basic tool management. Ensuring the right tool is being used for the job, alongside the most appropriate consumables, will play a key role in reducing the risk of HAVS.

There is a lot to be said for basic tool management. Ensuring the right tool is being used for the job, alongside the most appropriate consumables, will play a key role in reducing the risk of HAVS.

Ensure your employees have the most appropriate tools they need for the job in hand. As well as ensuring your operatives feel free to change tools as the task requires.

The most appropriate tools will reduce the overall vibration exposure as the job will be completed in the most efficient time possible.

Tool maintenance

Ensuring your tools and consumables are in good working condition is good practise for many health and safety reasons, not just reducing overall vibration. This includes ensuring cutting edges are not blunt and grinding pads are not balding for maximum efficiency and reduced vibration magnitude.

We recommend that you check all tools are up to date with their maintenance schedule and in good working condition. This will help to avoid increased vibration caused by faults or general wear.

Varying task and tool rotation

It is also worth reviewing tasks and job rotation when using vibrating tools to reduce the amount of time spent operating any one tool. By rotating tasks between operators long periods of time spent being exposed to vibration can be reduced.

Tool training

It is worth ensuring all operatives know how to correctly grip or handle each tool to maximise effectiveness without over-exposing themselves to vibration. Ensuring all operatives are fully training on each piece of vibrating equipment will help to reduce gripping or forcing a tool more than necessary.

We recommend that you include the following in your regular tool training and toolbox talks;

- HAVS training so operatives understand the dangers of vibration over-exposure and the symptoms of HAVS to look out for.

- HAVS training on how to prevent HAVS in the workplace and what to do if anyone experiences symptoms – it is worth noting here that it is an employers legal responsibility to report any HAVS symptoms or diagnosis’ to RIDDOR.

- Use of any vibration measuring and monitoring system that is in place

- Encouraging good blood circulation through keeping warm and dry and reducing smoking wherever possible as these factors have an adverse impact on how the body absorbs vibration.

- HAVS training that emphasises an employees responsibility to use any and all HAVS risk management measures that are put in place.

Measuring and Monitoring

Don’t forget, it is an employers legal obligation to ensure they are doing everything possible to reduce the risk of HAVS to as low as reasonably practicable.

Don’t forget, it is an employers legal obligation to ensure they are doing everything possible to reduce the risk of HAVS to as low as reasonably practicable.

Control measures are essential, but how do you know if they are enough to protect your operatives if you aren’t continuously measuring and monitoring their vibration exposure?

Discover HAVSPRO: the continuous measuring and monitoring system for vibration, that is rigidly fixed to the tool and not worn on the wrist.