Should We Continually Measure and Monitor Vibration?

Russ Langthorne explores this topic in the below blog post.

I recently listened to an article by a well respected occupational medicine consultant. This consultant has special interests in vibration related disease. And, as the article played, I was somewhat taken aback when he talked about continual monitoring… He advocated that we should continually monitor vibration exposure. This is contrary to the HSE advice, but 100% on track with ours!

Assumed Data?

So, you may think that a robust Risk Assessment could be done by timing how long it takes to drill 10 holes, and using that data to state in the Risk Assessment that you can drill x amount of holes, or, using the same methodology, how long it takes to cut an area of grass and then use the same type of calculation to create a risk assessment for cutting an area of grass.

Maybe you use assumed data? You could, add a tag onto the tool stating how long that particular tool can be used for, how many points per minute etc. Then, you may add that information onto a spreadsheet? Or, you ‘invested’ in an app that calculates the HSE points using the data that you have ‘meticulously’ created. Possibly, you are continually monitoring using a tool timing device loaded with assumed data from manufacturers or a library, HSE, or even measured in house?

The facts

It is a fact that 10% of tool users who regularly hit their EAV and WILL contract HAVS.

Last week I saw two different people on a construction site using the same Hilti SDS drill with the correct Hilti bit. Both people drilled into a concrete block. In 3 minutes one user accrued 4 HSE points…which you may think is high. The next accrued 15 HSE points in 3 minutes. This is using the same drill with the same bit, drilling the same block, why? It’s about the way he used the tool. Unfortunately, the consequences may have devastating effects on him and the business in the future.

The Solution

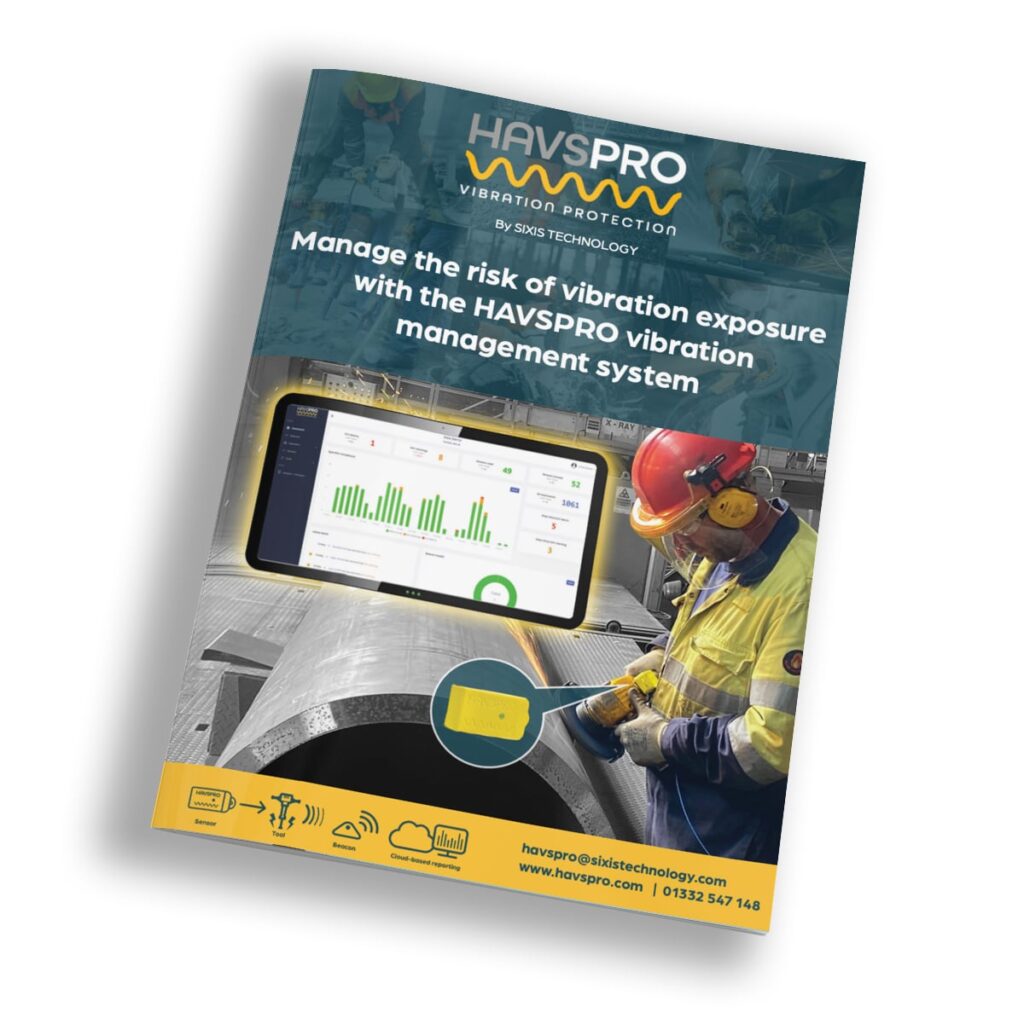

Now, imagine that you can continually measure and monitor every task. Next, imagine how effective and labour saving it would be if it was a simple task for the tool users to simply clip the device onto the tool, carry out the task, and then unclip the device. Finally, imagine how effective the Risk Assessments and subsequent actions would be when the safety team is guided by actual and accurate live data.

Continual MEASURING and MONITORING allows Health and Safety professionals to create Risk Assessments, simply, quickly and above all, accurately.

Continual Measuring and Monitoring is a great big YES and if we do, we can #MakeHAVSHistory

Follow us on LinkedIn for more content