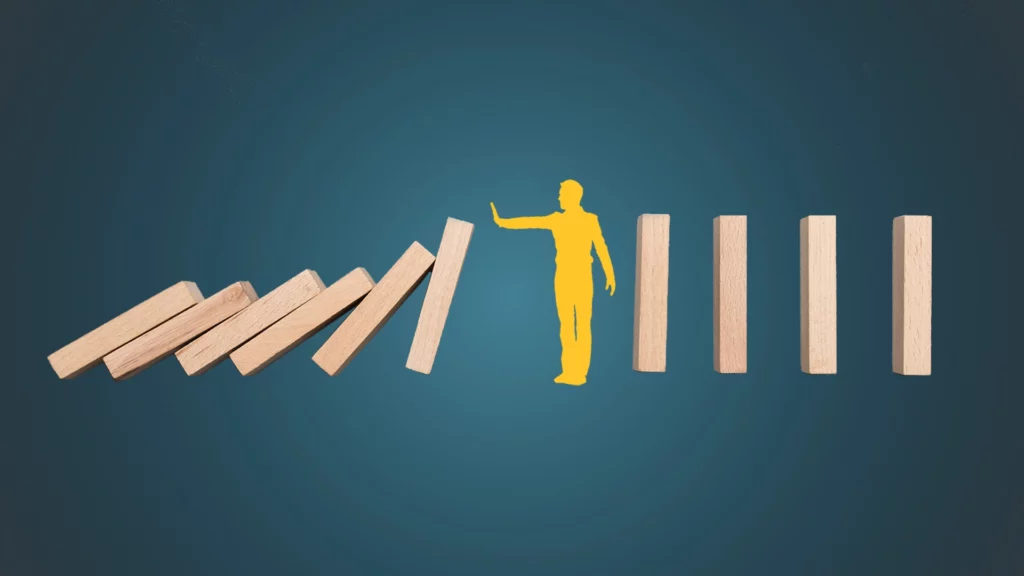

“Prevention is better than cure” or in this case (as cure is not possible with HAVS) it should be “prevention is better than (legal) defence. This is what a proactive HAVS risk management strategy does but what does it entail? And what is a reactive HAVS management strategy? Let’s take a look…

We all know that HAVS risk management is required by law (the Control of Vibration at Work Regulations 2005) but there is a difference between doing the essentials to meet the minimum requirements required by law and proactively protecting your staff to ensure their vibration exposure is limited to ALARP (as low as reasonably practicable).

We all know that HAVS risk management is required by law (the Control of Vibration at Work Regulations 2005) but there is a difference between doing the essentials to meet the minimum requirements required by law and proactively protecting your staff to ensure their vibration exposure is limited to ALARP (as low as reasonably practicable).

When it comes to vibration exposure, continuous measuring and monitoring or proactive risk management, is not something that the regulations require you to do by law. The regulations advocate that vibration exposure should be eliminated or reduced to ALARP. Where this is not possible you should manage the risk of vibration exposure to ensure operatives aren’t exposed to more than their EAV on a daily basis, or at worse, their ELV.

The HAVSPRO system advocates a prevention is better than cure (or defence in this case) approach and completely agree with the HSE in that vibration exposure should be eliminated wherever possible. But this isn’t always possible, so how can employers ensure they are proactively protecting their staff with a HAVS Risk Management strategy?

A proactive HAVS Risk Management strategy

There are two approaches you can take when it comes to managing the risk of vibration exposure; proactive or reactive.

- A reactive approach may use assumed vibration magnitude data, whether from the manufacturers documentation, the HSEs source of vibration magnitude data document, or vibration magnitude data from a limited period of monitoring. The problem with using any of these data sources as part of your HAVS risk management strategy is that there are so many variables that effect vibration magnitude. This means the values you are using to calculation exposure in HSE points may not give you an accurate representation of the exposure the operatives are actually experiencing.

Another important feature of a reactive strategy is that it highlights the risk when the exposure points are calculated into HSE points and NOT at point of exposure. This means the exposure or over-exposure has already occurred making any resulting actions or control measures reactive. This reactive approach is more likely to result in HAVS incidences as it can allow vibration over-exposure to happen and control measures to be implemented retrospectively if the exposure is calculated after the event. These cases are likely to end up in either legal or civil litigation. - A proactive approach is to measure and monitor vibration exposure (accurate, on-the-tool vibration magnitude as it is being experienced by the operator in real time) and use the alerts that tell you when operatives are reaching critical levels to implement control measures before over-exposure has had the chance to occur. A proactive strategy will effectively reduce the vibration exposure experienced by operatives before they reach dangerous levels, reducing the incidences of HAVS.

HAVSPRO is a proactive vibration risk management solution that provides a proactive HAVS risk management strategy.

The system;

- measures accurate vibration levels, as the operative is experiencing them,

- monitors them and then, and

- alerts you every time an operative hits their EAV, then 90% of their ELV and a third time when they hit their ELV.

It is designed to Make HAVS History, and the only way to do this is to ensure you are acting to reduce vibration exposure in real time.

The biggest flaw in the regulations and the other compliance-focussed solutions that are available on the market, is that they are designed to help organisations defend their actions in court – once cases of HAVS have been identified.

The biggest flaw in the regulations and the other compliance-focussed solutions that are available on the market, is that they are designed to help organisations defend their actions in court – once cases of HAVS have been identified.

HAVSPRO is designed to stop cases from arising, so there are less people effected with the debilitating effects of vibration over-exposure and therefore, less organisations ending up in court.

By basing your HAVS Risk Management strategy on risk assessments that use assumed (vibration magnitude) data and utilise tool timers, you are only ever basing risk on a guesstimate. This will always result in incidences of HAVS because the risk isn’t being accurately managed as vibration magnitude is susceptible to so many variables:

- Consumable condition

- Condition of the tool

- User handling

- Type of surface and substrate the tool is being used on

- The service history of the tool

The other significant problem with a reactive HAVS Risk Management strategy is that it won’t proactively alert you when an operative is breaching their safe vibration levels. You will only be able to identify over-exposure after the event, when it is too late to act to ensure the operative is safe.

In conclusion

The correct solution for you when managing the risk of hand arm vibration exposure depends on the reason you are implementing it.

If you want a strategy that complies with the letter of the law, then a reactive solution that focuses on legal compliance and courtroom defence will do the trick. Although, this strategy will not stop workers suffering in the long term.

If you want to proactively manage the risk posed to your operatives and ensure you are acting before vibration exposure becomes dangerous to them, you need a system that measures accurate, on-the-tool vibration magnitude and manages the data in the form of proactive alerts.

The purpose of risk management, whether it is vibration or any other health and safety matter, is that you are managing that risk to as low as reasonably practicable. Is it practicable to implement a proactive approach?

We think it is, so the only responsible strategy for managing HAVS risk is to accurately measure and proactively monitor vibration levels – ensuring you act BEFORE vibration levels become dangerous.

Prevent HAVS with proactive, effective risk management, don’t defend your strategy to a sufferer and a judge.

Download the HAVSPRO Brochure

Discover how HAVSPRO monitors vibration levels accurately and triggers alerts to protect your staff and organisation against the risks of HAVS and WBV (whole body vibration).

It monitors individual tool vibration levels and the exposure each person has to it.

HAVSPRO then collates all this data and creates customisable reports to help you prevent overexposure.

Find out everything you need to know in our brochure – simply complete the form!

Find out more about HAVSPRO and how it can help you protect your staff and business: 01332 547 148 or you can download our Employers Guide to HAVS