HSE vibration levels are set to protect workers who operate vibration-emitting tools, particularly hand tools (there are limits for whole body vibration but we will cover these in another article).

The limits are set by the HSE, who are the governing body that regulate the exposure to vibration levels for operatives. Vibration exposure is limited because it is an established fact that too much vibration can cause damage to hands and arms. More about this later, but let’s look at the limits first.

What are HSE vibration levels?

The HSE set two values that you must be aware of when managing the risk of hand arm vibration exposure; the EAV (exposure action value) and the ELV (exposure limit value).

The HSE state the following values represents a high risk above which employees should not be exposed:

- a daily EAV of 2.5 m/s 2A(8)

- a daily ELV of 5 m/s 2A(8).

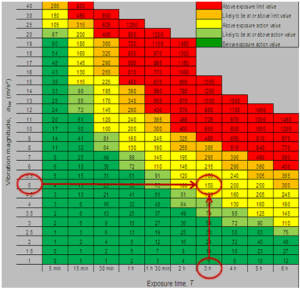

To simplify the calculation of vibration exposure, the HSE have created a points system that you must use to calculate the amount of vibration magnitude a person is being exposed to.

It is these points that you should use to calculate the HSE vibration levels (the EAV and ELV) that your operatives are being exposed to.

You can read more about calculating HSE vibration levels in points and how to use this data as part of the required risk assessment in our Guide to HAVS Risk Assessments and the consequences of getting it wrong.

So, what are the EAV and ELV in HSE points?

EAV is 100 HSE points and ELV is 400 points.

We must stress that these are legal maximum limits and employers may want to reduce these limits for vulnerable members of staff who may be more susceptible to the damage that can be caused by vibration exposure.

Why are HSE vibration levels important?

The Control of Vibration at Work Regulations 2005 requires employers to prevent or reduce risks to health and safety from exposure to vibration at work, but don’t forget, employees have duties under the regulations too!

So now we know what the HSE vibration levels are, what do they mean?

They mean that we must adhere to them when managing the risk of hand arm vibration and a failure to do so will result in catastrophic consequences for your operatives, and very damaging, costly outcomes for your business.

Firstly, EAV…

When an operator reaches their EAV (maximum 100 HSE points), there must be action taken to reduce the risk further.

This action could be;

- review the risk assessment findings and recommended actions,

- to rotate tasks to reduce exposure for a single person,

- change the method of working,

- to take a break and do a role that doesn’t require using vibrating tools, or

- to change the tool and/or consumables being used.

This will help to reduce the impact of vibration exposure for those operatives who simply can’t avoid using vibration tools as part of their daily tasks.

REMEMBER: The HSE recommend you should aim to not exceed the EAV for an individual each day. Whilst the ELV is the absolute maximum amount of vibration exposure an operative can be exposed to, the HSE will look for action to be taken to ensure an operators exposure doesn’t exceed their EAV.

Secondly, ELV…

When an operator reaches their ELV (maximum 400 HSE points), they MUST stop using vibrating hand tools for the rest of that day. They have reached the safe amount of vibration exposure for that 24 hour period and MUST NOT, by law, be exposure to any further vibration magnitude during that time frame.

HSE vibration levels, whether EAV or ELV, are there to protect both the employer and the employee from irreparable health conditions.

The HSE clearly warn that damage from HAVS (hand arm vibration syndrome) is preventable, but once the damage is done it is permanent, serious and disabling.

If employers don’t sufficiently manage the risk of vibration exposure, within the HSE vibration levels stated, they run the risk of legal prosecution, fines and compensation claims, not to mention all the time and reputation lost as a result.

If you are an employee who works with any sort of vibrating hand tools, you must also ensure you are not exposing yourself to more vibration than the regulations allow. They are there to protect you. For more information on the damaging effect of HAVS, visit the London Pain Clinic.

How should HSE vibration levels be measured?

So, how can you measure HSE vibration levels to make sure you are taking action when operatives reach their EAV and stopping exposure when they reach their ELV, all of which must be recorded once actioned?

The HSE say you need to create a risk assessment stating how much vibration a person will be exposed to. The risk assessment must also show what actions will be taken to reduce risk to ALARP (as low as reasonably practicable).

To create this risk assessment you will need 2 things;

- the vibration magnitude of the tool, and

- the amount of time the operative is using that tool for (sometimes known as the trigger time).

This information can then be entered into the HSEs Ready Reckoner to establish how many HSE vibration level points a person has been exposed to.

However, there are several things that this system doesn’t take into consideration:

- This is a static risk assessment and is only accurate as long as the data in it is accurate.

- The risk assessment isn’t dynamic and will only show you the risk based on that point in time, if any variable changes, the magnitude will change and the risk reported in the risk assessment will not be accurate.

- These static risk assessments use one-off vibration magnitude data (either measured at a point in time or using the HSEs Source of vibration magnitude data list) – both systems work on the assumption that vibration magnitude doesn’t change – and it does!

- These risk assessments don’t factor in the many variables that effect vibration magnitude, which effectively renders the assessment ineffective at managing risk because the data cannot be relied upon.

- The entire system is reactive as almost all HSE points are calculated at the end of the day or shift, when trigger time and assumed magnitude are punched into the ready reckoner. This doesn’t give the operator or the employer the opportunity to take action in real time, before it becomes too great a risk.

The only way to be 100% confident that you are not over-exposing your operatives to the risks posed by vibration magnitude, is to continuously measure and monitor vibration magnitude.

However, this directly contravenes the guidelines from the HSE who state that continuous measuring and monitoring of vibration data is not necessary and uses up too much time and money.

But what if you could do it affordably and in less time than it currently takes to complete the associated risk assessment tasks?

Should vibration levels be continuously monitored?

When the HSE created the control of vibration at work act 2005, it would’ve been expensive and very time consuming to continuously measure and monitor vibration exposure levels because the technology simply wasn’t available to enable it.

However, this is no longer the case and, in fact, technology has now made it cheaper and much more time-effective to implement a system that continuously measures and monitors vibration magnitude, in the form of HAVSPRO.

However, this is no longer the case and, in fact, technology has now made it cheaper and much more time-effective to implement a system that continuously measures and monitors vibration magnitude, in the form of HAVSPRO.

The system measures vibration magnitude in real-time, and is firmly fixed to the vibrating surface of the tool, in-line with British Standard 5349 2 4.1.4.2 which states that “the accelerometers should be rigidly attached to the vibrating surface.”

This gives you accurate, real-time vibration data, that it calculates into HSE points for you, and then sends you text and email alerts when an operative’s EAV is reached, when they hit 90% of their ELV and again when they reach their ELV.

This means you can let the technology do the heavy lifting in terms of measuring, accuracy of vibration magnitude data, nuances of vibration magnitude caused by many variables, and monitoring exposure levels in relation to limits reached.

You can proactively manage the risk of vibration exposure, and ensure you are keeping your operatives safe and within the legal HSE vibration levels, AND free up your supervisors from time-consuming form filling and trigger time recording – not to mention the amount of time someone then has to take to punch this data into the HSE ready reckoner to complete the risk assessments.

The HAVSPRO system means you can proactively manage the risk of HAVS to as low as reasonably practicable for those operatives who can not eliminate vibration exposure from their working day.

HSE vibration levels in summary

It is critical that employers AND employees understand the grave dangers inherent in using hand held vibrating tools, and the very important regulations that are in place to protect operatives who use them.

It is critical that employers AND employees understand the grave dangers inherent in using hand held vibrating tools, and the very important regulations that are in place to protect operatives who use them.

As part of this, the regulations use HSE points, to ensure operatives aren’t over-exposed to vibration levels and these MUST be adhered to.

The most cost effective and time-efficient way of managing the risk of vibration exposure and ensuring you are 100% compliant with the regulations is to use a system such as HAVSPRO, which continuously measures and monitors accurate, real-time vibration exposure and allows you to proactively reduce the risk as and when it occurs.

Download the HAVSPRO Brochure

Discover how HAVSPRO monitors vibration levels accurately and triggers alerts to protect your staff and organisation against the risks of HAVS and WBV (whole body vibration).

It monitors individual tool vibration levels and the exposure each person has to it.

HAVSPRO then collates all this data and creates customisable reports to help you prevent overexposure.

Find out everything you need to know in our brochure – simply complete the form!

Find out more about HAVSPRO and how it can help you protect your staff and business: 01332 547 148 or you can download our Employers Guide to HAVS